SkyAzur’s expertise as an industrial process design office :

auditing, design and complete industrial processes

From the presentation of your idea to the making of a prototype and the compilation of a mass production preparation file, we can manage all the stages of your project. Our unique, comprehensive approach ensures confidentiality and cost control.

Contact us ! Whatever your request, our team of engineers and technicians are there for you to propose solutions adapted to your specific needs.

Our industrial process design office has developed a process for analysing your project and needs, thus helping respond effectively to your problems.

By offering a new and neutral perspective on current production principles, our engineers and technicians develop fresh, effective working hypotheses. For this analysis phase, we work in collaboration with internal or external teams and gather both objective and subjective data. Once information gathering is completed, the experts from our industrial process design office develop hypotheses, submit them to your teams and test them against internal constraints.

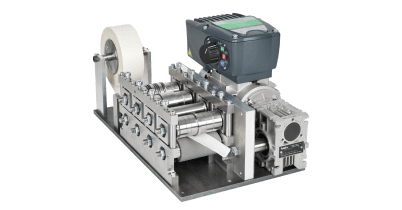

This preparatory work helps us come up with innovative hypotheses or test out an innovative function, via digital simulation, lab testing, prototypes, etc...

Our industrial process design office relies on a proven project methodology.

Once you have expressed your problems, we work on an in-depth understanding of your needs in order to define them precisely. This step involves a functional analysis phase and the gathering of data needed for the project.

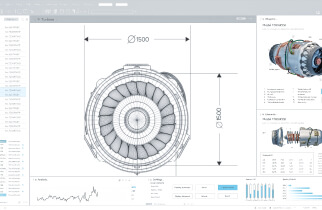

Once the pre-project phase is completed, our engineers conduct a feasibility study and begin the search for optimal production processes, before proposing suitable technical solutions. Once our solutions are validated, the equipment is 3D-modelled using CAD (Computer-Aided Design).

Our experts integrate your industry standards as well as trade-specific aspects into their work processes in order to respond optimally to your constraints. The ergonomics of the developed solutions are also examined to ensure optimal user comfort.

To ensure proper monitoring of your project, we provide you with the following deliverables for each project :

Industrial process design offices play a critical role in the manufacturing landscape, providing specialised expertise in order to optimise operations and stimulate innovation. The heart of their mission is a commitment to research and development (R&D), engineering, design, project management, analysis and consulting.

Design offices set themselves apart by their ability to explore new ideas and push the envelope of innovation. They invest in ongoing research to anticipate emerging trends and integrate the latest technological advances into their solutions. R&D feeds a proactive approach, offering clients solutions that anticipate their future challenges.

At the crossroads of engineering and design, these offices transform concepts into tangible reality. Their expertise in designing complex systems and optimised production processes guarantees maximum operational efficiency. Starting with a blank sheet, they bring to life custom-made solutions that respond precisely to each client’s needs.

Project management is a core competence for industrial process design offices. From planning to implementation, they ensure transparent coordination among the various stakeholders. This guarantees on-time project delivery on budget and in compliance with the most demanding standards.

Design offices set themselves apart by their ability to analyse existing industrial processes in depth. They identify inefficiencies and improvement opportunities, providing strategic advice in order to maximise operational performance. Their ingenuity unlocks solutions that exceed expectations to resolve issues with agility.

Calling on the services of an industrial process design office offers an immersive experience in innovation and efficiency, going well beyond simple outsourcing. You get the assurance of an ongoing source of innovation, guided by experts on the cutting edge of technological advances. Custom solutions and optimised processes lead to unmatched operational efficiency and generate significant productivity gains.

Furthermore, experts ensure transparent project management, on time and on budget. This holistic approach puts clients in a good position for sustainable growth and continuous adaptation to market changes. In the end, an industrial process design office is not just a service provider, but rather a strategic partner that contributes to operational excellence and competitiveness on today's dynamic industrial market.