Would you like to validate your project with a prototype or prove or disprove the basis for one or more concepts involved in this project, prior to any commercial validation ? SkyAzur puts its manufacturing expertise to work in industrial prototyping for your projects.

Contact us : We can provide you with a tailor-made response !

As an expert in industrial engineering, SkyAzur designs and manufactures special-purpose machines, industrial tooling, test benches and facilities in accordance with precise specifications. Our comprehensive offer includes analysis of industrial needs, design, sizing, execution, installation on site, training and after-sales support.

Thanks to advanced management of technological upgrades and innovations, we optimise our design and manufacturing services every day. Our team of engineers and technicians are there for you to propose an end product adapted to your specific needs.

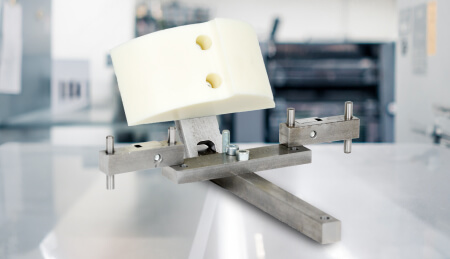

We are proud to present our specialised tooling offer for specific applications, reflecting our cutting-edge expertise in this field. This range includes various types of tools carefully designed to respond to specific needs in a variety of industrial processes.

Our services include assembly tools designed to ensure that assembly processes are efficient and precise. Furthermore, our offer includes test tools to ensure end product quality and compliance. We also supply specialised gauges for welding as well as for dimension testing, in order to optimise production processes and ensure high-quality results.

This diversity of specific tools reflects our commitment to supply fit-for-purpose solutions that meet the unique requirements of each client and each industrial application.

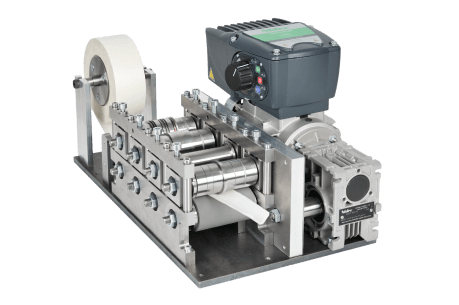

SkyAzur engineers and technicians have developed specialised expertise in the design and production of special-purpose machines based on specifications, with a varied offer that responds to the specific needs of our clients.